Lighting installation is often one of the most time-consuming parts of a project—not because lighting is inherently complex, but because traditional wiring methods multiply work at every step.

From routing power lines to installing and testing drivers, small inefficiencies quickly add up. This is why many projects fall behind schedule long before the lights ever turn on.Understanding where the time goes is the first step toward installing lighting faster, with fewer complications.

1. Where Installation Time Is Really Spent

Most delays don’t come from installing the fixture itself. They come from everything around it.

Traditional setup typically requires:

• One driver per fixture

• Individual power connections

• Multiple junction boxes

• Repeated testing for each light

As fixture count increases, installation time grows linearly—or worse. Four lights don’t take four times the time. They often take six to eight times the effort once wiring, testing, and troubleshooting are included.

2. The Hidden Cost of “One Driver Per Light”

The traditional one-driver-per-fixture approach seems straightforward, but it creates several compounding issues:

• More components to mount

• More failure points

• More time spent labeling, testing, and reworking

On site, this often means:

• Congested ceilings

• Hard-to-reach drivers

• Longer commissioning time

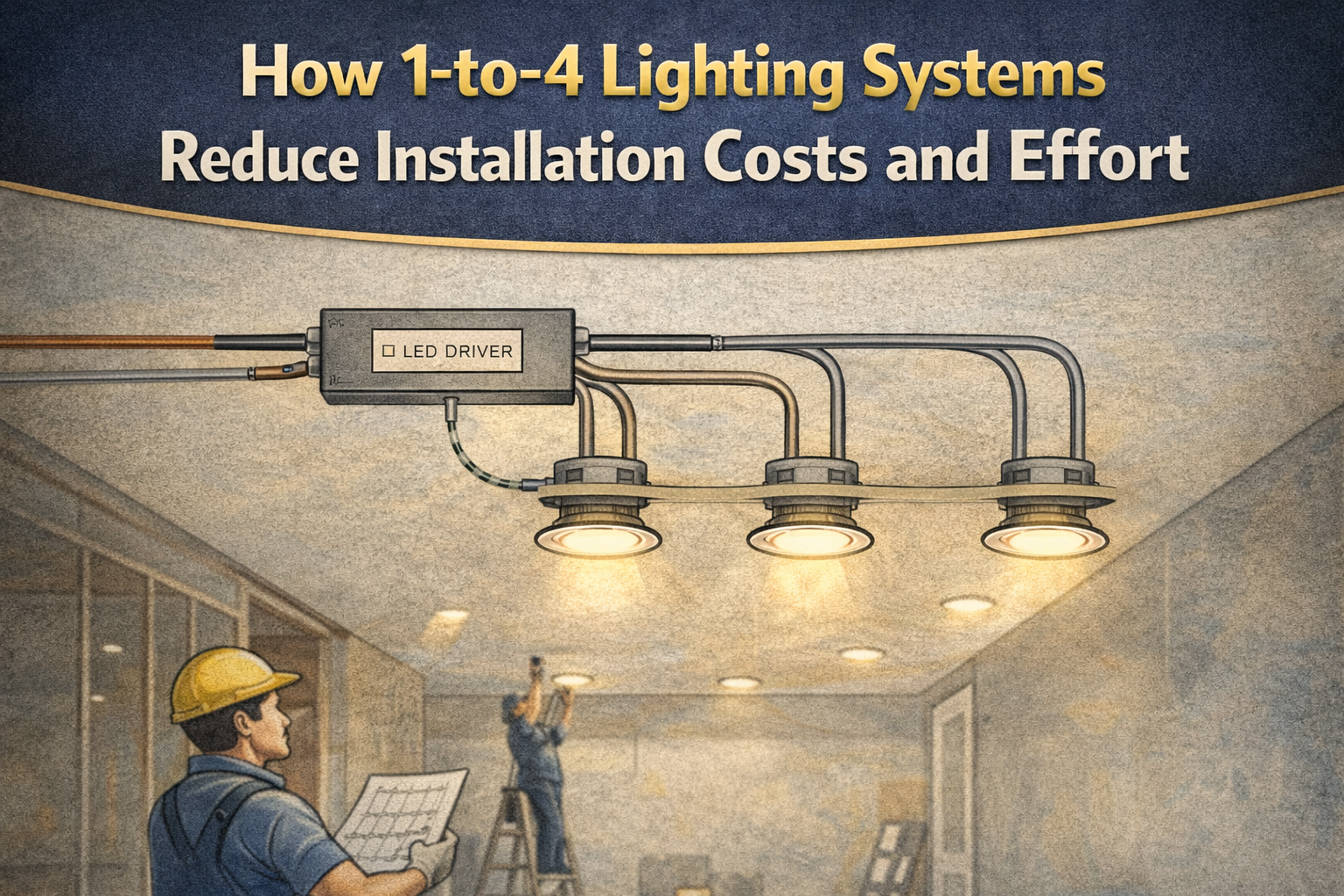

3. Solution: Use 1-to-4 Systems Change the Installation Process

A 1-to-4 lighting system uses a single driver to power multiple fixtures. While conceptually simple, this shift fundamentally changes the workflow. With a 1-to-4 system:

A 1-to-4 lighting system uses a single driver to power multiple fixtures. While conceptually simple, this shift fundamentally changes the workflow. With a 1-to-4 system:

• One driver replaces four

• Low-voltage wiring runs between fixtures

• Fewer junction boxes are needed

• Driver placement is centralized and planned

The result is a shorter, cleaner installation sequence. Instead of repeating the same steps four times, crews complete them once.

4. Why Installation Becomes Faster (Not Just Cheaper)

Time savings come from more than fewer parts. Key efficiency gains:

Time savings come from more than fewer parts. Key efficiency gains:

• Reduced wiring complexity

• Fewer ceiling penetrations

• Simplified testing

• Less on-site troubleshooting

5. When 1-to-4 Systems Make the Most Sense

1-to-4 systems are not a universal solution—but in the right context, they are extremely effective. Ideal applications:

• Uniform lighting zones

• Spaces that do not require individual dimming

• Areas with limited ceiling depth

• Projects prioritizing speed and consistency

It’s just as important to know where not to use this approach when:

• Individual fixture control is required

• Complex dimming or smart controls are planned

• Long-term flexibility is a priority

• Maintenance access is limited or poorly planned

6. Final Thought: Faster Installation Starts With Fewer Decisions on Site

Lighting installation takes so long not because lighting is complicated—but because too many decisions are pushed to the job site.

1-to-4 systems move complexity upstream, where it can be solved once instead of repeatedly. Used in the right places, they don’t just save time.

They reduce friction, errors, and long-term headaches.

Share:

Light in Layers: How Spaces Gain Rhythm and Depth